APPLICATIONS

-

GANTRY LOADER

-

TARNAR

-

ROBOT

APPLICATION 01

GANTRY LOADER

This is a gantry loader application with a total length of 160 meters. It consists of five gantry loaders, eight conveyors, and seven QC stations. Users can achieve an integrated processing line from materials to finished products.

Gantry Model

Weight capacity: up to50kg

| Axis | Unit | Speed |

|---|---|---|

| Z-axis | Carrier | 120m/min |

| Y/V-axis | Arm | 90m/min |

Installation of products

- Gantry Loader5 units

- Conveyor8 units

- QC station7 units

Total length:160m

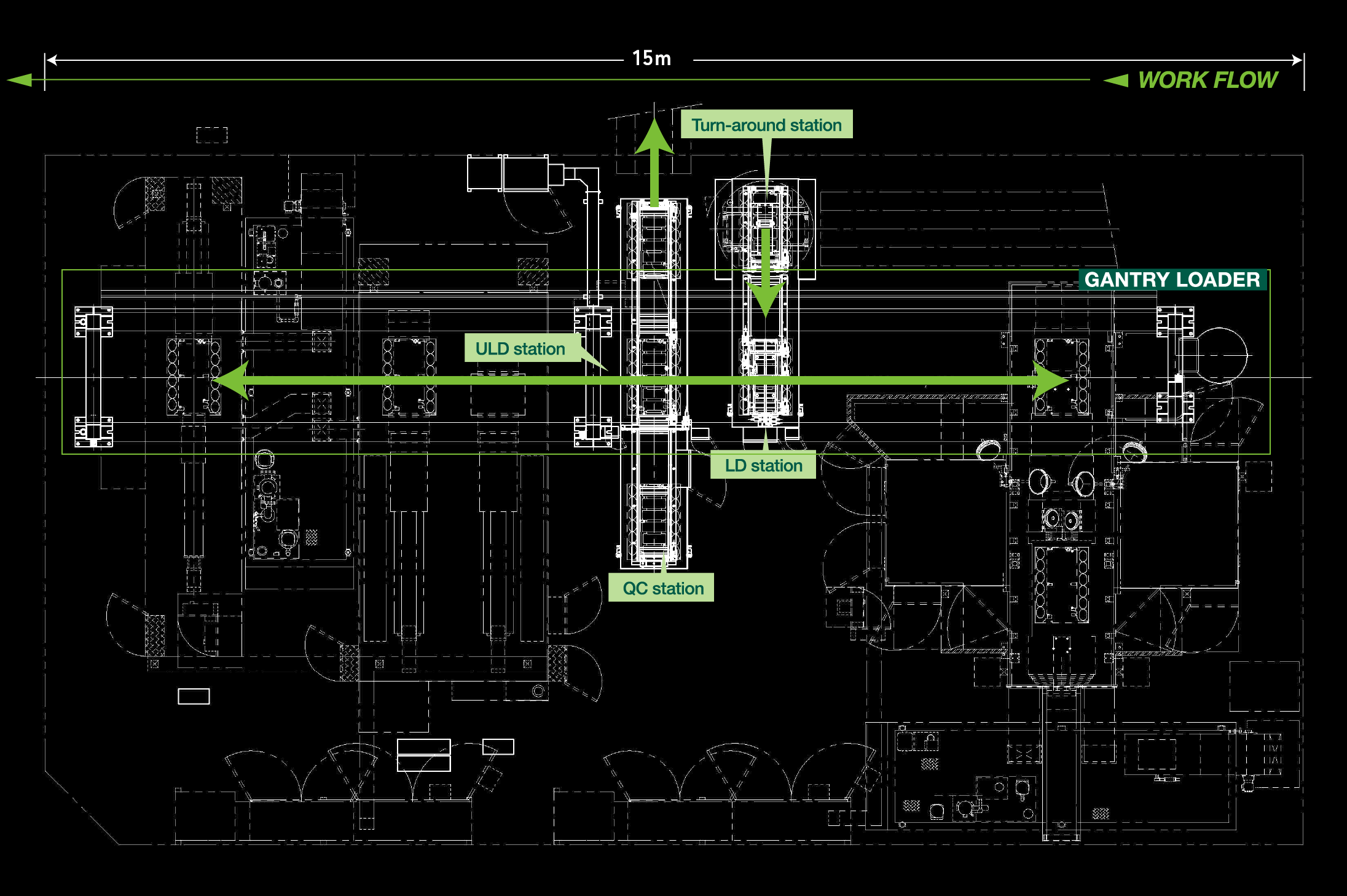

APPLICATION 02

GANTRY LOADER

A gantry loader application with a payload capacity of 500 kilograms. It consists of one gantry loader, two conveyors, and one turntable. This application is beneficial for reducing the operator's lifting tasks or when the robot lacks sufficient payload capacity.

Gantry Model

Weight capacity: up to500kg

| Axis | Unit | Speed |

|---|---|---|

| Z-axis | Carrier | 30m/min |

| Y-axis | Arm | 30m/min |

Installation of products

- Gantry Loader1 units

- Turn-around station1 units

- QC station1 units

- ULD station1 units

- LD station1 units

Total length: 15m

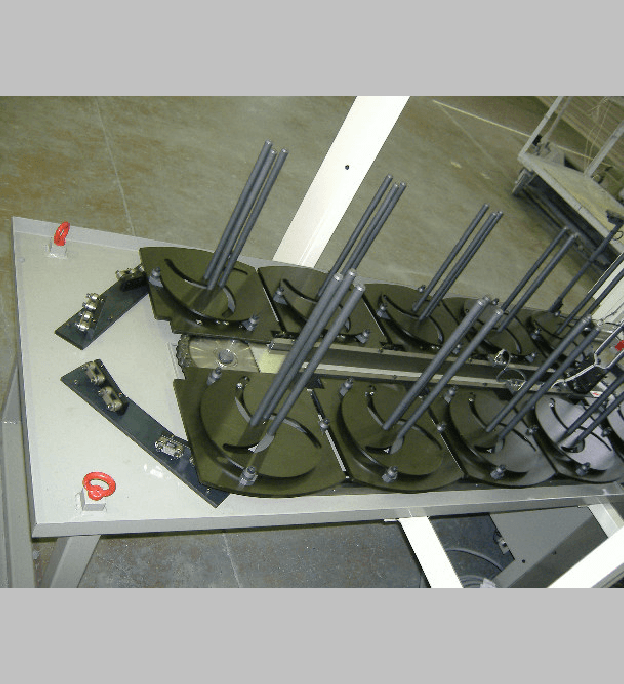

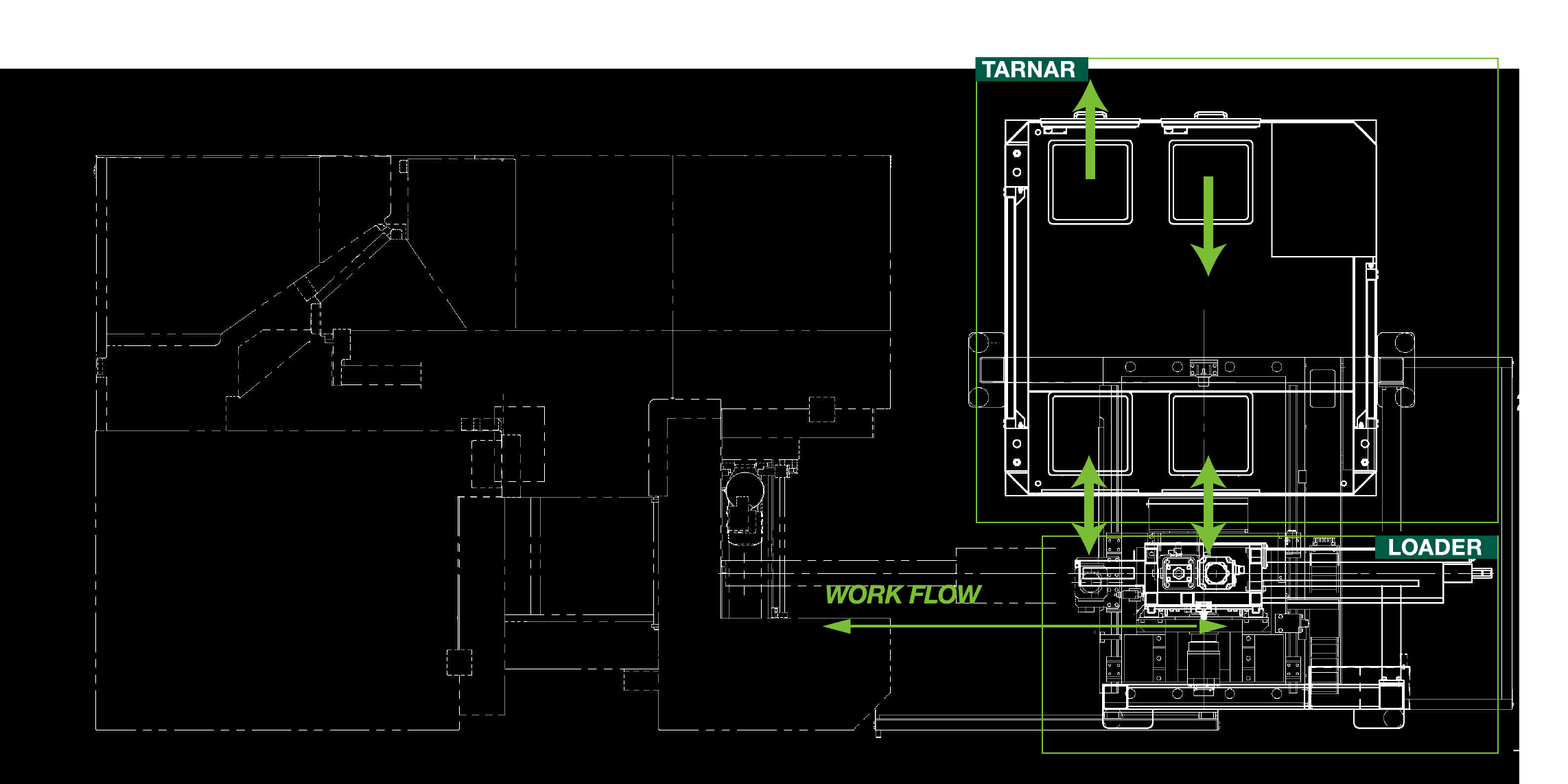

APPLICATION 03

TARNAR / LOADER

This application uses a Tarnar to achieve high-mix automation in a compact area of only 12 m2. The application consists of one loader and one Tarnar. Tarnar works well with robots, facilitating application proposals that leverage the advantages.

Gantry Model

Weight capacity: up to10kg

| Axis | Unit | Speed |

|---|---|---|

| Z-axis | Carrier | 40m/min |

| Y-axis | Arm | 40m/min |

| X-axis | Shift | 40m/min |

Installation of products

- TARNAR1 units

- Loader1 units

Total length: 6m

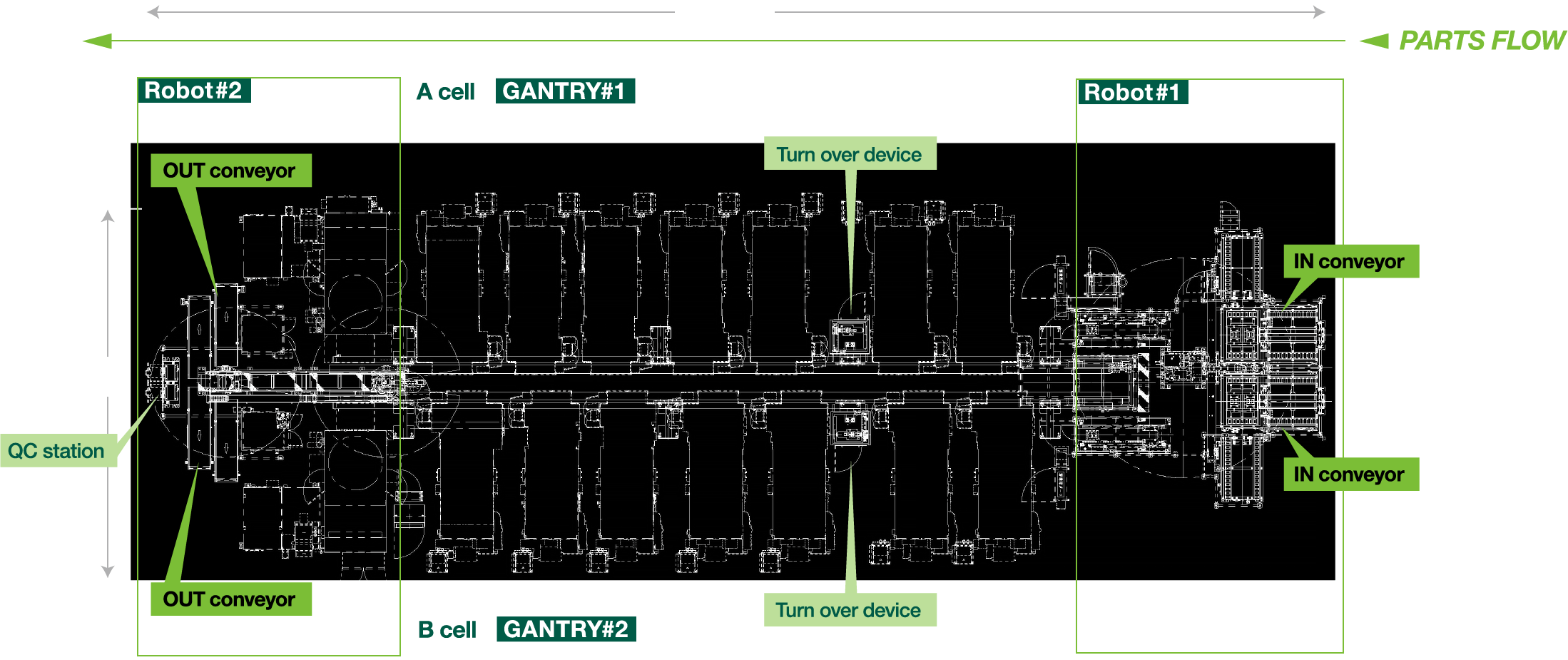

APPLICATION 04

ROBOT / GANTRY LOADER

This is a collaborative application between a gantry loader and a robot. The application is composed of a robot for supplying materials, a gantry loader for the machining process, and a robot for the cleaning and measurement process. Very few manufacturers can handle all these processes in-house; however, we are able to offer integrated Hamana quality.

Gantry Model

Weight capacity: up to5kg

| Axis | Unit | Speed |

|---|---|---|

| Z-axis | Carrier | 120m/min |

| Y/V-axis | Arm | 90m/min |

| X-axis | Shift | 50m/min |

Installation of products

- Robot2 units

- Gantry Loader2 units

- Conveyor4 units

- Turn over device2 units

- QC station1 units

Total length: 28m

SYSTEM

for APPLICATION

We also manufacture incidental devices.

-

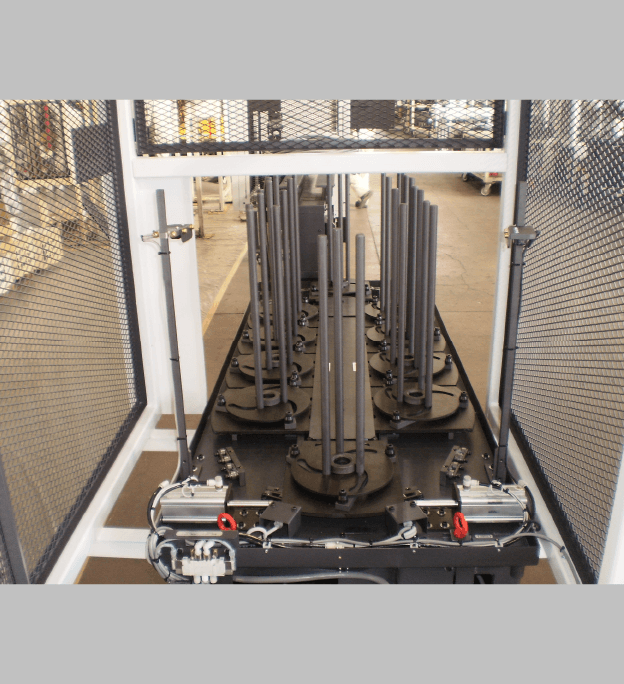

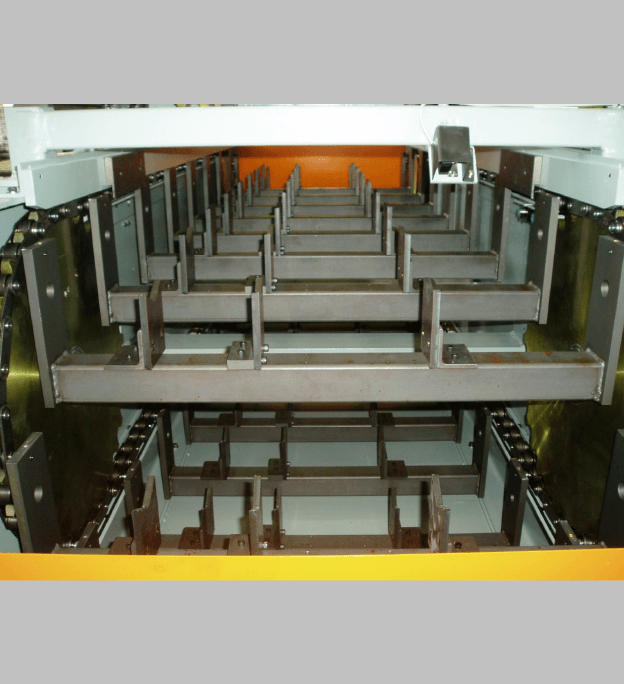

TARNAR

Features

Max. loading capacity (1 pallet) 25kg Pallet exchange time 20seconds Number of palletsStand-alone Automated Two-row specification 40pieces 30pieces Single-row specification 20pieces 15pieces CustomizableCustomizing the pallet makes it possible to store various workpieces in one unit.

It can also be used as a stand-alone automated warehouse for storing standard stock, tools, etc.

- ・Worktable

- ・Cradle conveyor

- ・Roller conveyor

- ・Top plate conveyor

-

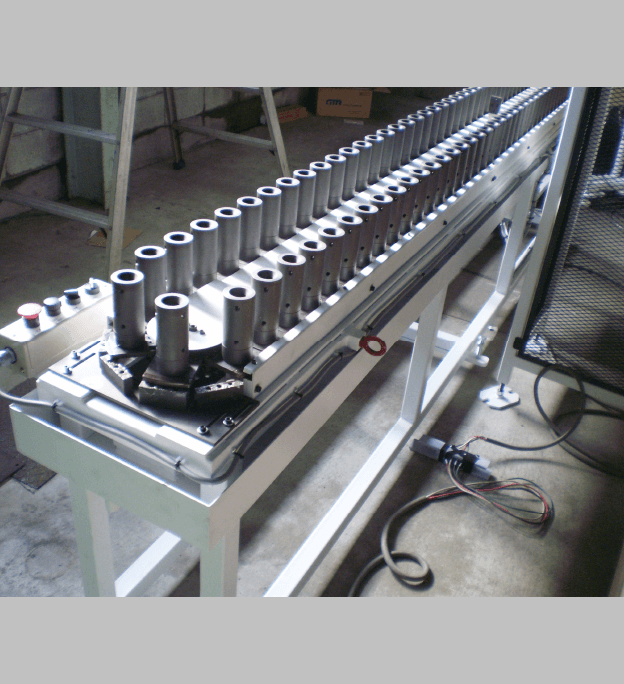

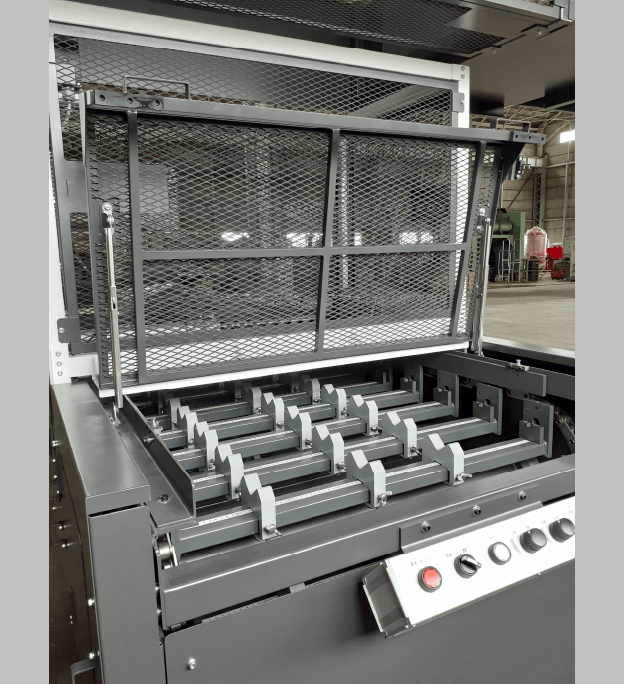

Worktable

A standard worktable for stockers.

The pallet size and number of stations can be customized according to work size and installation space.Features

Pallet size 150 mm diameter, 250 mm diameter Number of stations 10 stations 20 stations Number of lifters 1, 2, none -

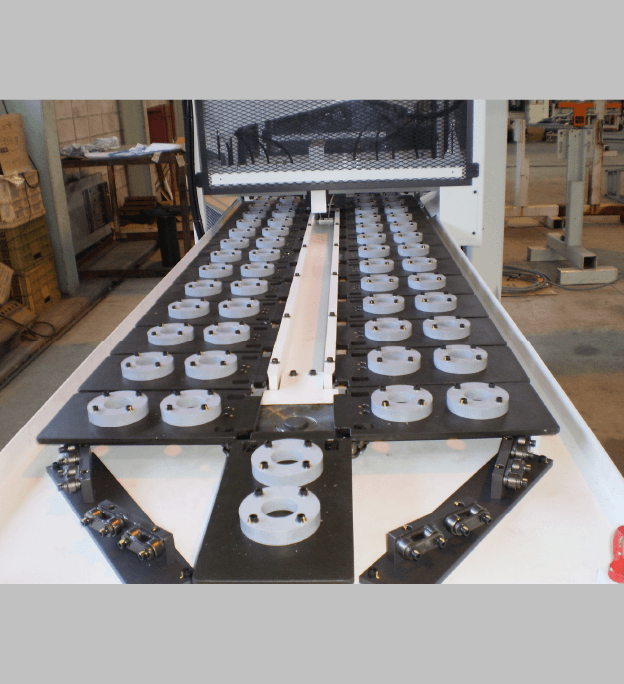

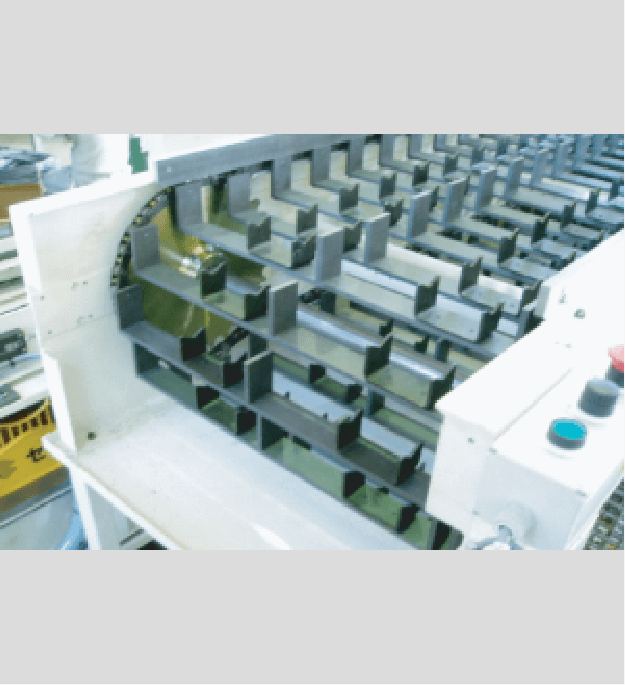

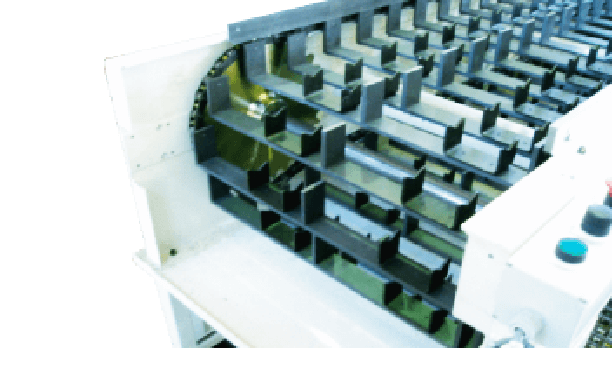

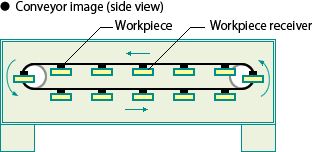

Cradle conveyor

This conveyor always keeps the top of the pallet facing upwards (like a Ferris wheel).

The conveyor can be rotated forward and backward, so both first-in and first-out operation is supported for workpieces.

-

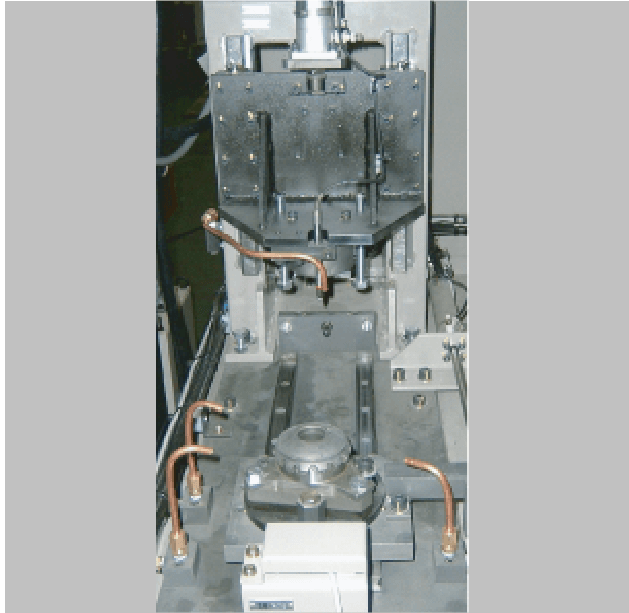

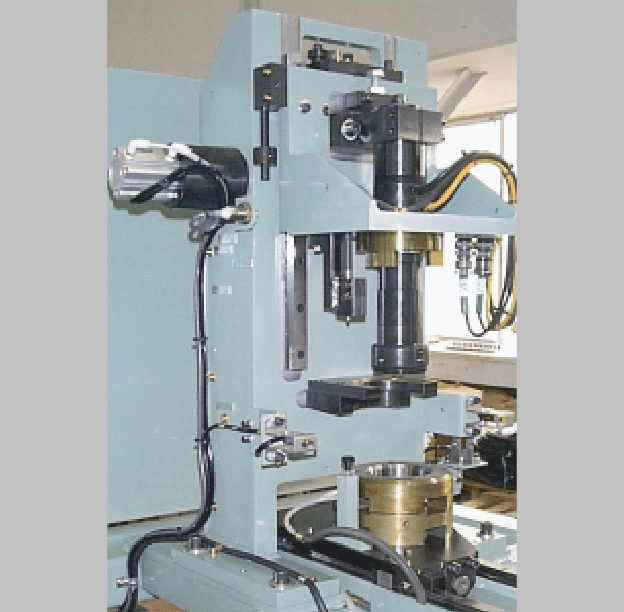

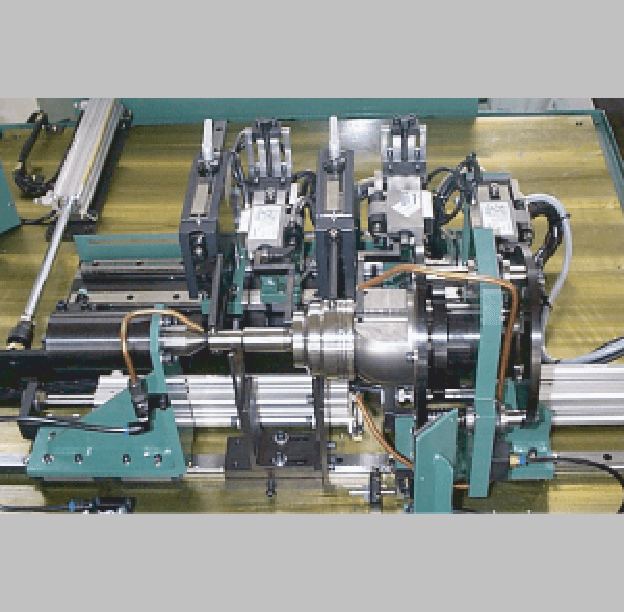

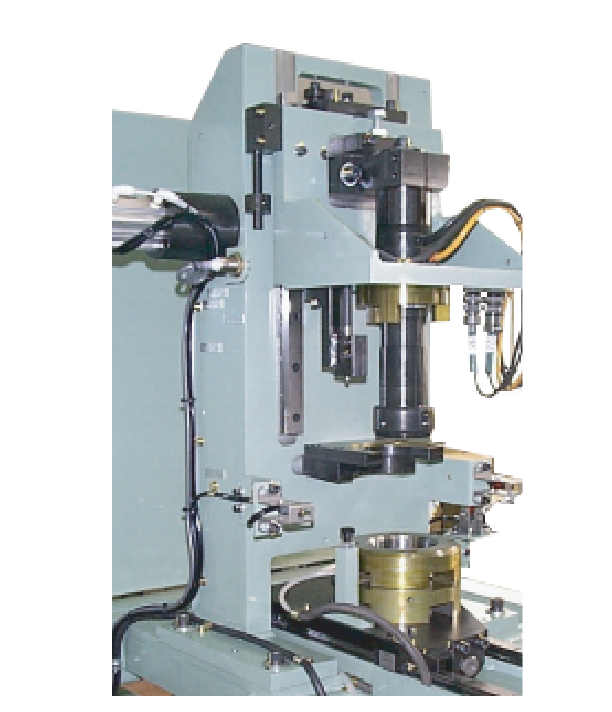

DEVICE

- ・Measuring device

- ・Stamping device

- ・Cleaning (air blowing) device

- ・Quality check device

PRODUCTS & APPLICATIONS